Quality Inspection

Ensuring Quality and Reducing Human Errors

Ensuring Quality and

Reducing Human Errors

AI-Based Detection, Unbiased Inspection Standards

By standardized AI detection, we ensure quality control in product inspections. Conducting product inspections with AI effectively eliminates losses caused by human errors, fatigue, omissions, and misjudgments, thereby enhancing product inspection quality while reducing manpower and cost expenditures.

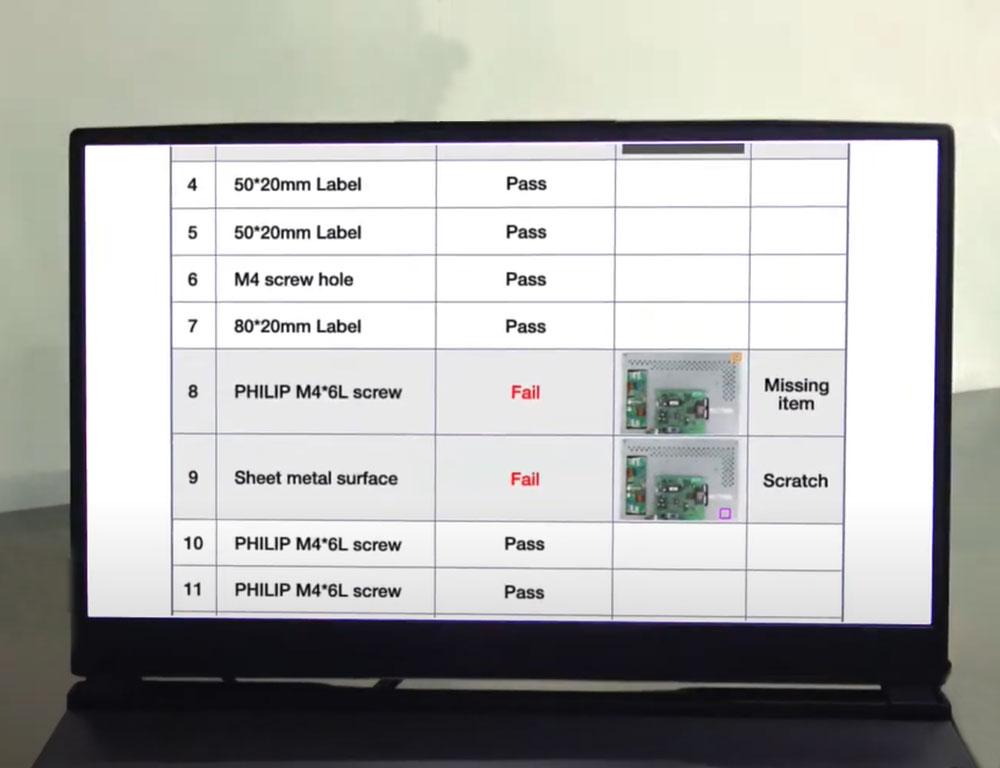

Automatically Generating Digitization Inspection Reports

With digitization technology, the inspection process automatically generates and stores digital inspection reports. These inspection reports are comprehensively archived, ensuring the reliability of the data, while also improving work efficiency and providing convenient access to report data.

5G Private Network Application, Establishing a Comprehensive AIoT Environment

By Taiwan Mobile's 5G private network applications, a seamless AIoT environment with flawless spots can be established. This eliminates the need for deploying a large number of Wi-Fi base stations in the factory premises and enables reliable Wi-Fi signals to be accessed throughout the entire area, anytime and anywhere.

Explore Alternative Solutions

Hybrid Training

With the integration of virtual and physical technologies, combining virtual 3D images with entity models for practical operation, storing and sharing expert knowledge, training costs are minimized, flexibility and efficiency are enhanced.

Learn moreEquipment Maintenance

Through AI-guided instructions and assistance, maintenance personnel are empowered to improve repair quality, minimize downtime, address human errors, and enhance equipment operational stability and production line efficiency.

Learn moreFactory Inspection

Using AIoT technology in inspections, real-time recording, interpretation, and notification of factory information is enabled. With navigation and step-by-step guidance, inspections can be conducted without omissions, and the reliability of reports can be enhanced.

Learn more