AIR|Customized AI AR Application

Implement AIR to Enhance Work

Efficiency Rapidly

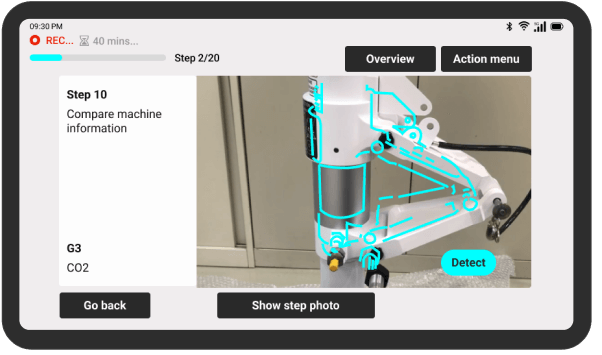

AI Detection Addresses Human Errors

AI detection identifies equipment anomalies, improper operations, or defective products, prompting real-time alerts and fix procedures. Effectively eliminates human errors from inexperience, fatigue, negligence or insufficient alertness - preventing losses like production downtimes, industrial accidents, equipment damage.

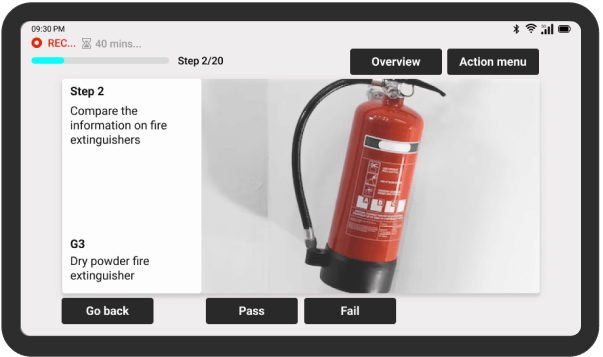

Step-by-Step Guidance Simplifies Instructions

The optimized SOP presents instructions through illustrated cards with images, text, and voice guidance. This enables personnel to easily follow and execute tasks, effectively reducing operational errors. It allows even beginners to quickly grasp complex equipment operations and reduces training costs.

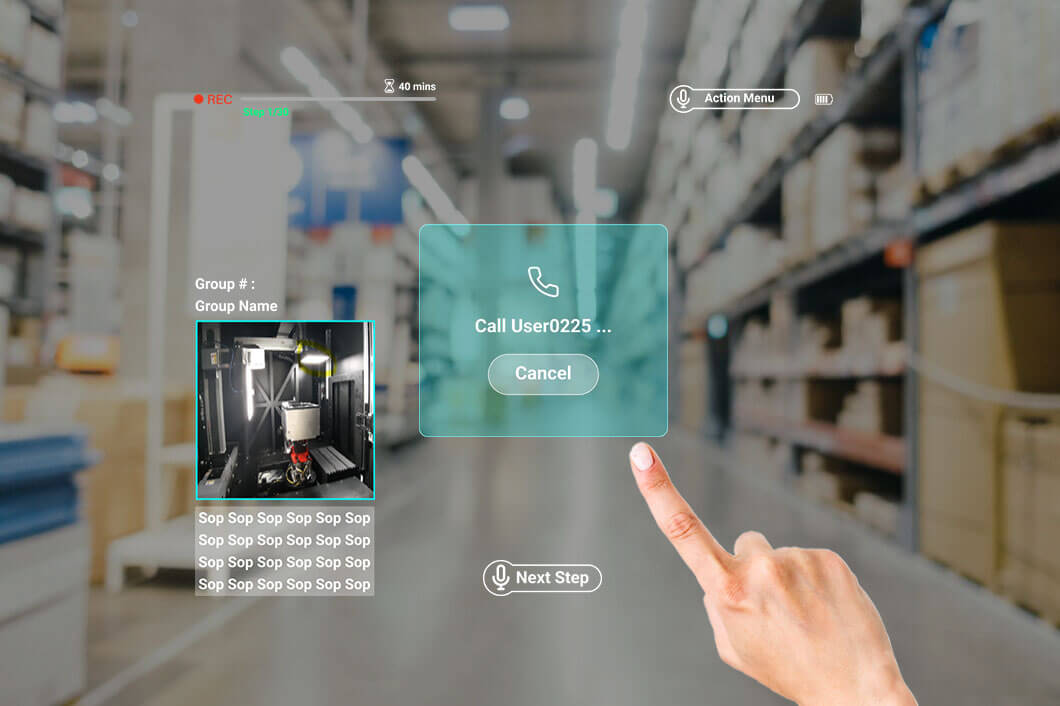

AR Visual Guidance Improves Work Efficiency

AR technology provides clear maps and shortest route guides for comprehensive inspection in minimal time. Visual guidance also frees up hands - eliminating needs to check paper manuals during tasks - reducing operation errors and improving efficiency.

Customize Diverse AIR Functions

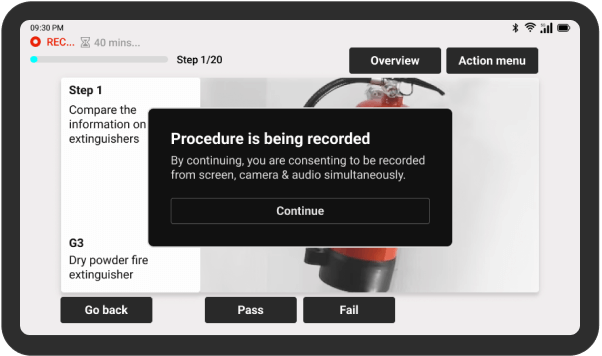

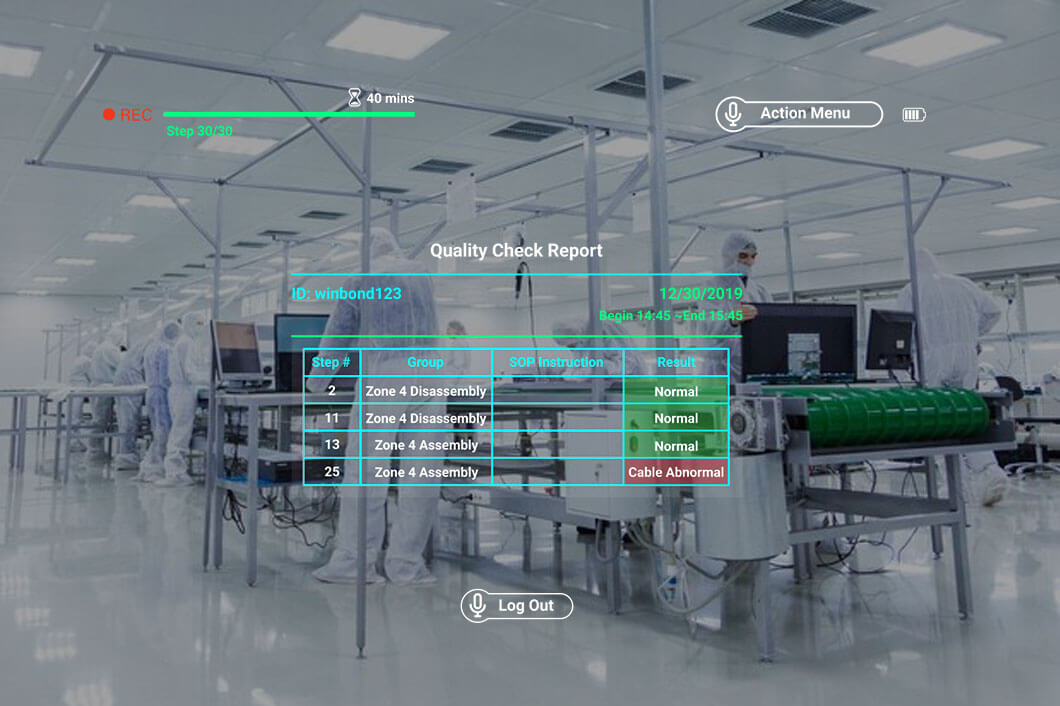

Full Video Recording

Record personnel operations to ensure a complete record of operations is available for review at any time.

AI Detection

Leverage AI to detect equipment anomaly, improper operations, or defects in production line. Ensures accurate and error-free task execution.

Illustrated Instruction Cards

Clearly prompt each action step to lower the probability of operational mistakes.

AR Visual Guidance

Provide checkpoint maps, optimal route guides, or AR navigation for comprehensive inspection in minimal time.

Remote Expert

Call remote experts for collaboration, with video screening to protect confidential data.

Auto-Generate Digital Reports

System auto-generates digital inspection, quality, maintenance reports after tasks end, averting inaccurate records from human errors.

Explore Solutions Applicable to AIR

Hybrid Training

With the integration of virtual and physical technologies, combining virtual 3D images with entity models for practical operation, storing and sharing expert knowledge, training costs are minimized, flexibility and efficiency are enhanced.

Learn moreEquipment Maintenance

Through AI-guided instructions and assistance, maintenance personnel are empowered to improve repair quality, minimize downtime, address human errors, and enhance equipment operational stability and production line efficiency.

Learn moreFactory Inspection

Using AIoT technology in inspections, real-time recording, interpretation, and notification of factory information is enabled. With navigation and step-by-step guidance, inspections can be conducted without omissions, and the reliability of reports can be enhanced.

Learn moreQuality Inspection

Using AI anomaly detection in IPQC or FQC, product losses resulting from human factors are significantly reduced, leading to enhanced product inspection quality, decreased manpower requirements, and reduced cost expenditures.

Learn more