Total Solution for Factory Inspection:

Integrating Software, Hardware, and Communication

Total Solution for

Factory Inspection:

Integrating Software,

Hardware,

and Communication

In collaboration with Taiwan Mobile Enterprise Business, ADAT harnesses AI image detection technology with 5G-equipped iPad mobile devices. This total solution adeptly addresses key challenges in factory inspection:

Incomplete and Inaccurate SOP Execution

Due to the complexity of the inspection process, standardization is challenging. This results in incomplete and inaccurate execution of inspection steps, leading to difficulties in effectively addressing abnormal conditions.

Limited Detection of Abnormalities in Real Time

The conventional inspection approach lacks the capability to promptly and effectively identify human errors and abnormal conditions. This deficiency increases the risk of downtime or shutdown, impacting overall production operations and subsequently raising operational costs.

Lack of Immediate Abnormal Alerts

The conventional inspection model struggles to promptly signal abnormal conditions and track inspection reports, leading to delayed handling of anomalies and subsequently escalating management expenses.

Streamlined 4-Step Inspection with 1 Single Click

The 5G AI Inspection GO software boasts full functionality and a user-friendly interface. With a simple click, you can seamlessly execute four inspection stages: AI reading, anomaly identification, report generation, and photo documentation.

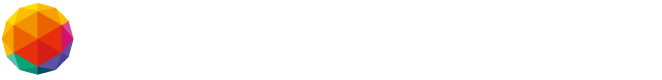

AI-Powered Versatility in Meter and Gauge Reading

5G AI Inspection GO offers a wide range of detection and reading capabilities, encompassing analog and digital gauges, light signals, switches, and more. Real-time alerts amplify its effectiveness.

Applications in Diverse Industries

5G AI Inspection GO provides convenient, swift, and cost-effective digital transformations tailored to a wide range of sectors, including power, chemical, petrochemical, semiconductor, traditional manufacturing, and electronics industries.