Equipment Maintenance

Improving Efficiency and Resolving Anomalies

Improving Efficiency and

Resolving Anomalies

Achieving Accurate Equipment Maintenance on The First Implementation

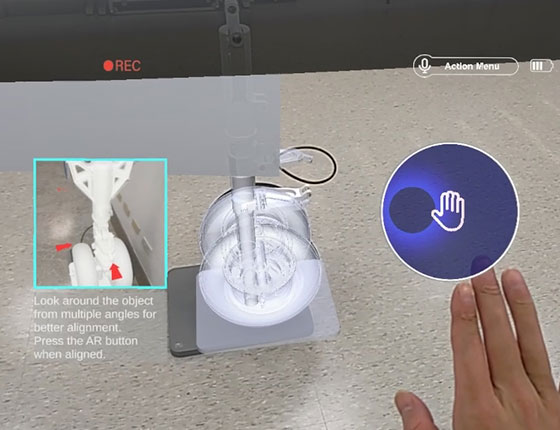

By using an AI app to guide equipment maintenance inspections, an AI coach provides clear repair instructions and anomaly detection, assisting on-site personnel in resolving equipment abnormalities and ensuring successful repairs. This approach effectively tackles issues caused by human factors, such as negligence, lack of experience, and operator errors, guaranteeing accurate equipment maintenance on the first implementation.

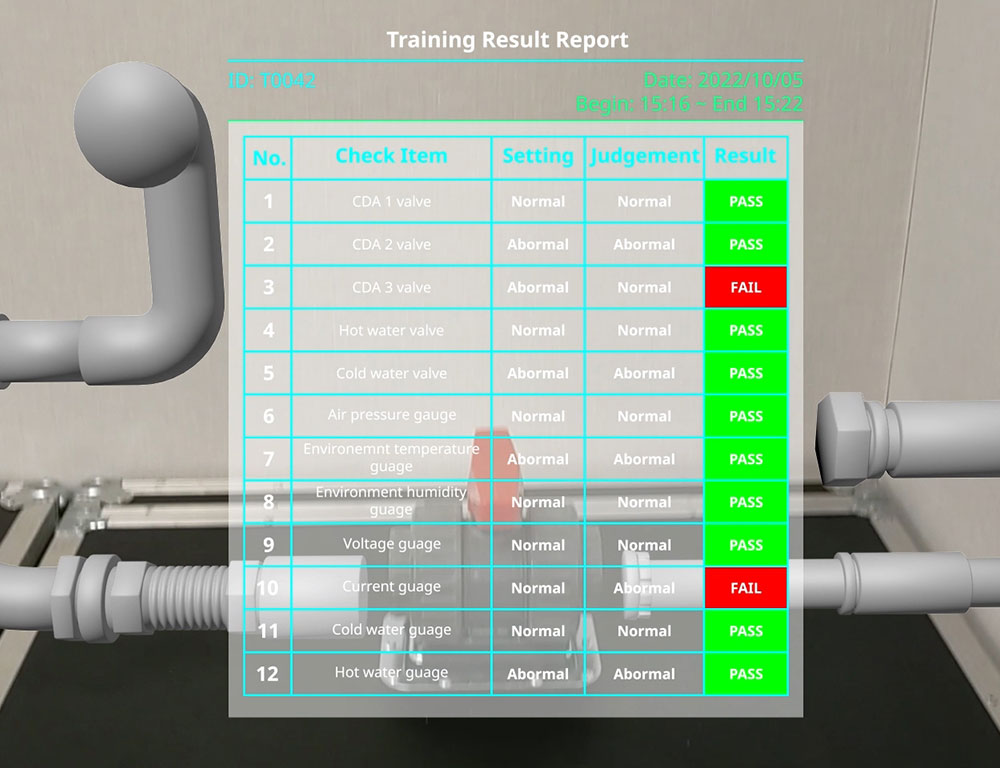

Automatically Generating Digital Quality Control Report

With digitization technology, recording the entire maintenance process in detail, automatically generating and saving digital quality control reports, enabling easier grasp to report data and enhancing work efficiency.

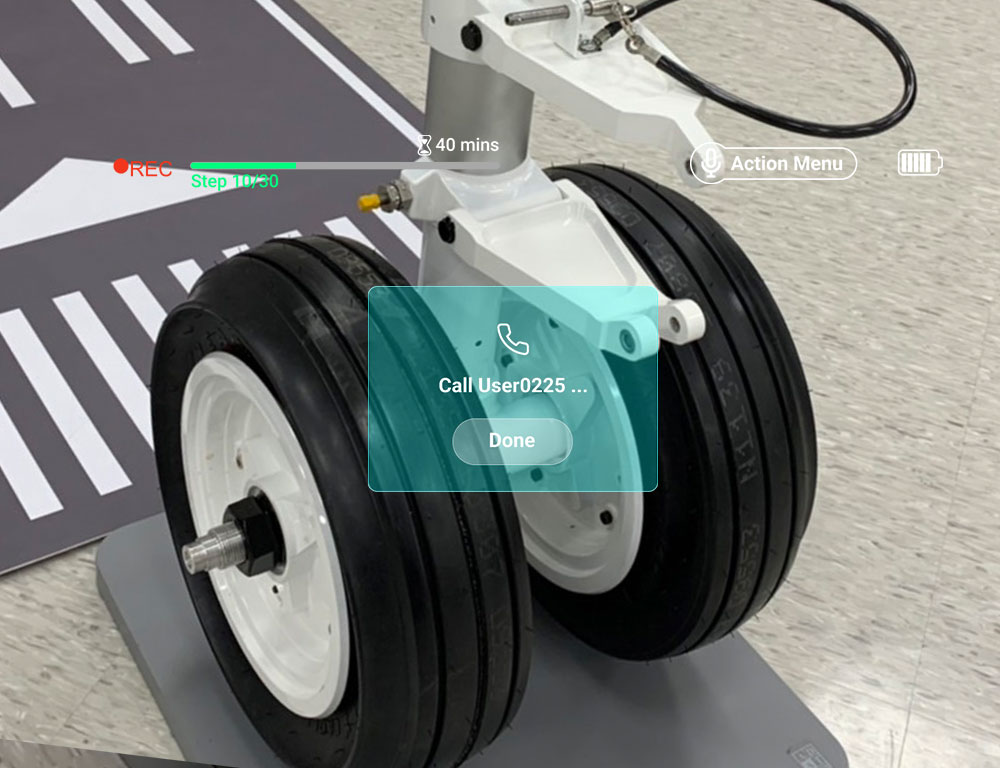

Instant Collaboration with Remote Experts

With the real-time remote expert connection feature, operators can engage in video calls and 3D mixed reality interactions with remote experts, accessing their expert guidance to solve problems. The remote mode blocks out any video footage beyond the machine operations to prevent any confidential information from being leaked.

Explore Alternative Solutions

Hybrid Training

With the integration of virtual and physical technologies, combining virtual 3D images with entity models for practical operation, storing and sharing expert knowledge, training costs are minimized, flexibility and efficiency are enhanced.

Learn moreFactory Inspection

Using AIoT technology in inspections, real-time recording, interpretation, and notification of factory information is enabled. With navigation and step-by-step guidance, inspections can be conducted without omissions, and the reliability of reports can be enhanced.

Learn moreQuality Inspection

Using AI anomaly detection in IPQC or FQC, product losses resulting from human factors are significantly reduced, leading to enhanced product inspection quality, decreased manpower requirements, and reduced cost expenditures.

Learn more