Factory Inspection

Intelligent Monitoring,

Reducing Operation and Maintenance Costs

Intelligent Monitoring,

Reducing Operation and

Maintenance Costs

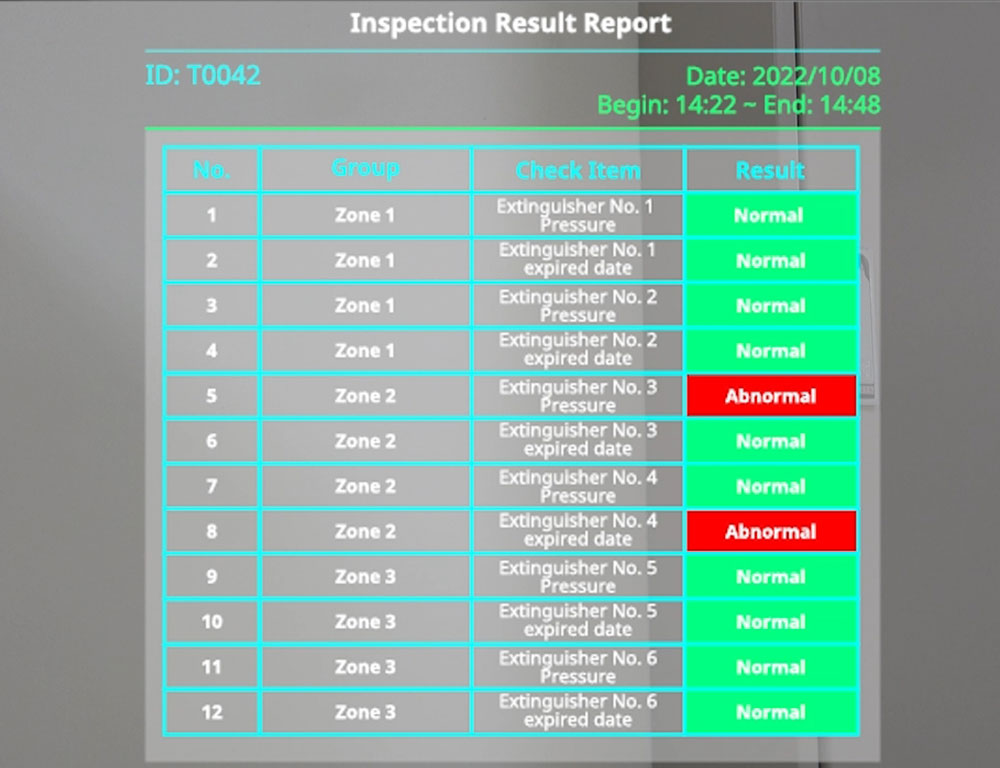

Automatically Generates Digital Inspection Reports

During factory inspections, the system automatically stores, logs, and generates inspection reports, thereby enhancing the credibility of the reports.

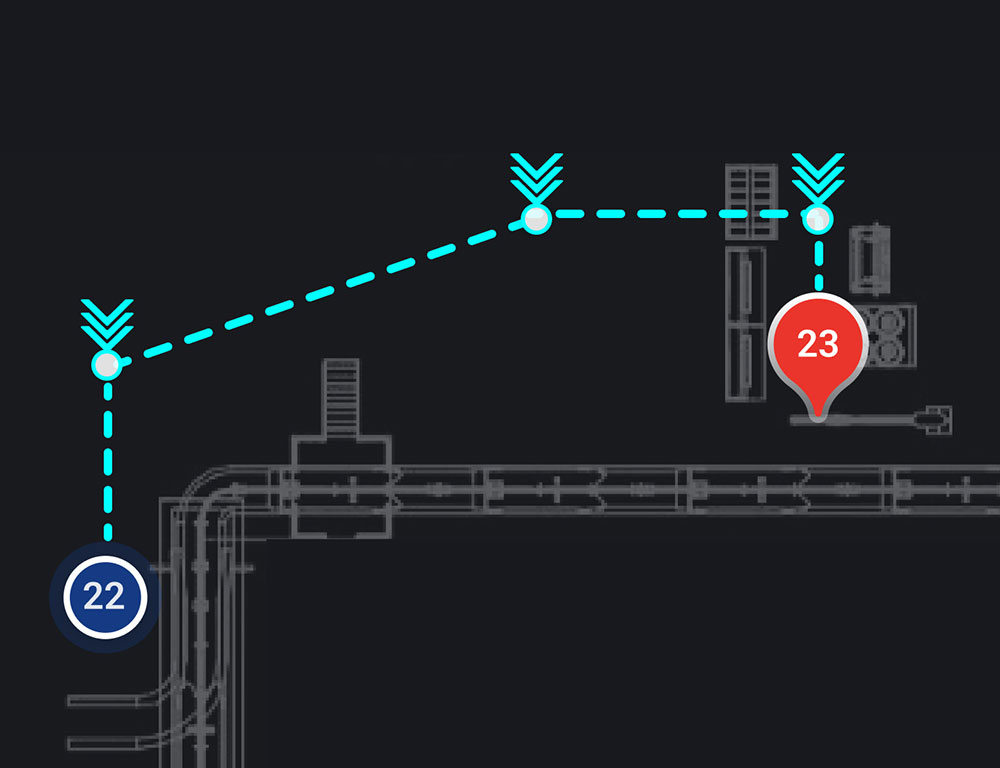

Standardized Inspection Process, Full Execution of Inspections

The system pre-plans the best routes and task assignments in advance to shorten the inspection time. It manages and ensures that personnel are physically present for inspections effectively, preventing missed inspections due to human factors and enhancing both inspection efficiency and quality.

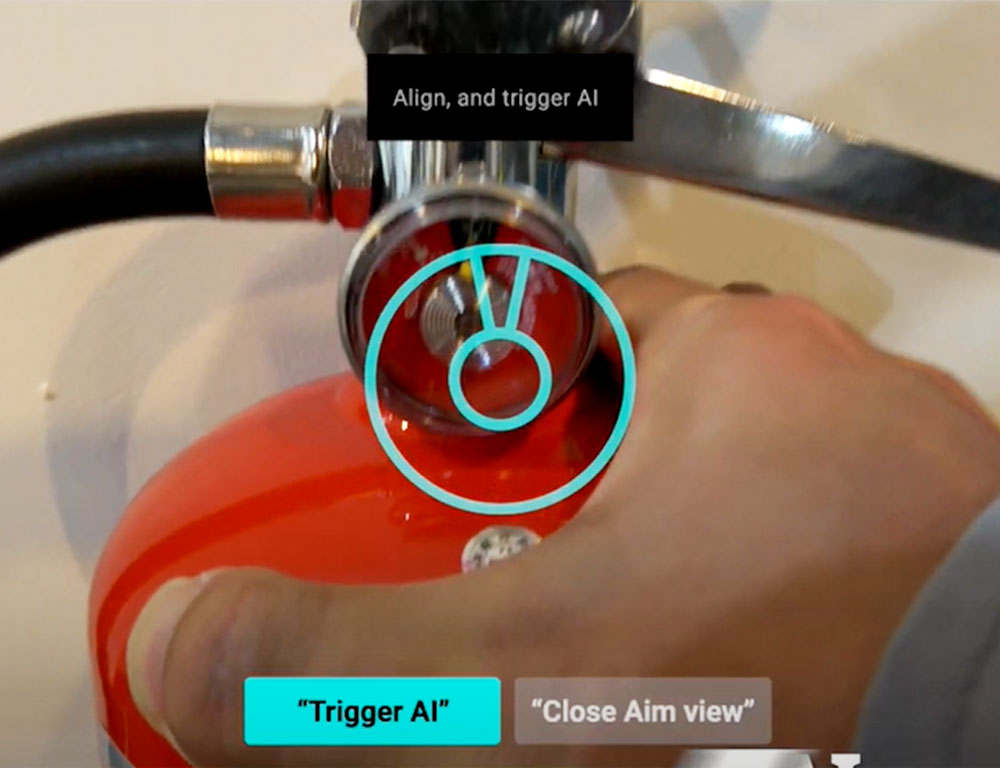

Real-time Recording and Monitoring

Through an AI-powered real-time monitoring system, the data are interpreted and recorded, and instant anomaly alerts are received at the central control room.

Explore Alternative Solutions

Hybrid Training

With the integration of virtual and physical technologies, combining virtual 3D images with entity models for practical operation, storing and sharing expert knowledge, training costs are minimized, flexibility and efficiency are enhanced.

Learn moreEquipment Maintenance

Through AI-guided instructions and assistance, maintenance personnel are empowered to improve repair quality, minimize downtime, address human errors, and enhance equipment operational stability and production line efficiency.

Learn moreQuality Inspection

Using AI anomaly detection in IPQC or FQC, product losses resulting from human factors are significantly reduced, leading to enhanced product inspection quality, decreased manpower requirements, and reduced cost expenditures.

Learn more